Wood pellets production tips

How are pellets made? This is a question that is frequently asked by many people. Here below are some few tips as to how it is done.

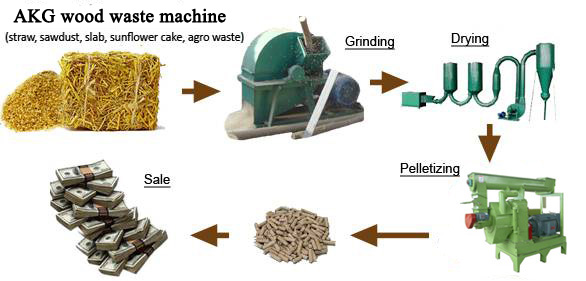

Pellet mill process:

In North America and various other countries across the world, raw materials are brought to the pellet mill everyday. The raw materials can be in many different forms and may be lumber mill scrap, sawdust, wood chips or even full trees that are not suitable for lumber. These raw materials can be freshly cut or green. They can also be kiln dried or partially dry. The processing of these raw materials in the same way leads to the production of end product that has moisture content that is consistent and standard quality burn, ash content and heat value characteristics. The manufacturers of pellets must ensure that they are of high standards so if the pellet appliances are to heat and burn in a consistent way.

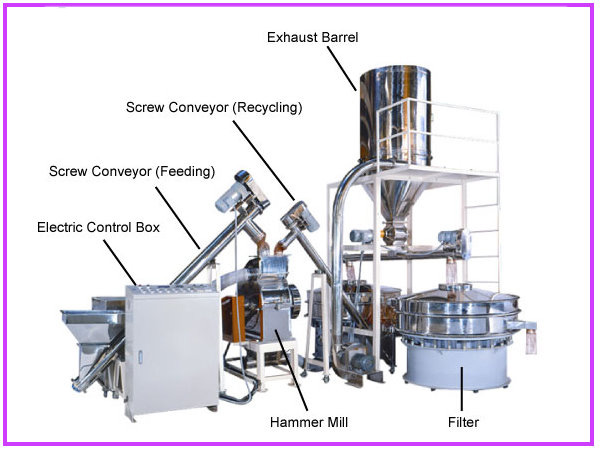

Chippers and hammer mills:

Some pellet making plants begin their process of production by putting large wood pieces through a pellet making machine which does the chipping of wood. These are necessary only for those mills which accept this feed-stock that is not uniform. There are various configurations that the pelletizer may need to be set at depending on the source of raw material. Although some of the manufacturing companies do not have chippers, most of them have hammer mill at the beginning of the process of milling. These machines are designed to take wood chips and sawdust after which they are broken down in to smaller sizes that are consistent so as to make the process of pressing and drying through pellet consistent and quicker.